The Ultimate Guide to Choosing Reusable Bulk Plastic Containers

Wiki Article

[=image]

[/video][=mkeyword]Reusable Bulk Plastic Containers[/mkeyword]

Understanding the Advantages of Bulk Containers in Enhancing Product Handling and Distribution Processes

Bulk containers play an essential role in optimizing product handling and distribution. Their style assists in effective stock administration and lessens waste, leading to cost financial savings. Furthermore, these containers boost transport effectiveness and enhance product safety throughout transit. As industries proceed to look for sustainable options, the flexibility of mass containers ends up being significantly pertinent. Discovering their numerous advantages reveals understandings that can transform functional techniques across supply chains. What might these insights involve for future practices?The Duty of Bulk Containers in Inventory Monitoring

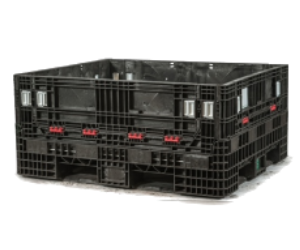

Bulk containers play a vital function in supply administration by improving the storage space and transport of big quantities of items. These containers assist in efficient company and easy accessibility to products, thus decreasing the moment spent situating products within warehouses. Their standard sizes and styles allow for optimum use of room, maximizing storage space capabilities. Furthermore, bulk containers improve the precision of supply tracking, as they can be easily classified and scanned for stock management systems. The durable nature of these containers protects items from damage throughout handling and transportation, making sure item stability. On the whole, bulk containers add considerably to a much more arranged, efficient, and trusted inventory monitoring process, supporting organizations in fulfilling demand and maintaining functional efficiency.[#image]

Cost-Effectiveness of Mass Containers

The cost-effectiveness of mass containers plays a substantial duty in contemporary product handling. By reducing product packaging costs and maximizing transportation logistics, companies can accomplish significant financial savings. This economic efficiency not only enhances success but likewise adds to structured procedures.

Minimized Product Packaging Expenses

Lots of organizations locate that utilizing bulk containers especially minimizes product packaging prices. By combining products into bigger containers, firms can substantially reduce the amount of packaging material required. This decrease not just reduces the expenses connected with purchasing packaging supplies yet additionally decreases waste disposal costs. Furthermore, bulk containers streamline the packaging procedure, enabling faster and more reliable packaging operations. Consequently, labor prices associated with taking care of smaller sized plans are additionally minimized. Additionally, the durability of bulk containers frequently leads to less product problems during transit, therefore reducing the need for substitute packaging. Generally, the adoption of bulk containers stands for a critical technique to minimizing product packaging expenditures while boosting operational performance.Efficient Transport Savings

Significant financial savings in transportation prices can be accomplished via making use of mass containers. By taking full advantage of load capabilities, mass containers decrease the variety of trips needed to move goods, bring about lower fuel costs and lowered labor costs. Their standard dimensions promote efficient packing and piling, enhancing area within transportation vehicles. Furthermore, mass containers often weigh much less than conventional packaging, permitting increased hauls without exceeding weight limitations, further boosting price performance. The toughness of these containers decreases item damages throughout transportation, lowering losses and returns. Overall, the integration of bulk containers in logistics not only streamlines transportation processes but also substantially adds to cost-effectiveness, making them a vital component in modern supply chain management.

Minimizing Waste With Bulk Containers

Mass containers play an essential role in reducing waste within product handling systems - [#mkeyword]. By reducing material waste and advertising reliable source use, these containers add considerably to sustainability initiatives. This shift in the direction of lasting packaging services not only profits the setting however also enhances operational performanceMinimizing Material Waste

Effective monitoring of product waste is an important worry in product handling, and making use of bulk containers can play a critical role in resolving this problem. By raising the quantity of materials carried at one time, mass containers significantly reduce the variety of shipments required, therefore minimizing excess product packaging waste. Their robust design additionally avoids spillage and damages during transportation, additional restricting material loss. Furthermore, bulk containers are often multiple-use, promoting a round economy that urges sustainability. The standardization of these containers simplifies supply administration and lowers the risk of over-ordering, which can bring about waste. As companies endeavor for efficiency, taking on mass containers emerges as a reliable strategy for reducing material waste in different distribution processes.Reliable Resource Use

While intending for optimal performance, lots of organizations discover that the application of bulk containers considerably boosts resource administration. These containers assist in structured operations by minimizing the regularity of dealing with and transport, which consequently decreases the likelihood of product loss and damages. By settling products right into larger systems, business can maximize storage room and decrease the requirement for too much product packaging. This approach not only reduces material prices but also reduces labor linked with dealing with smaller bundles. Additionally, bulk containers commonly have a longer life expectancy contrasted to typical product packaging, bring about lower substitute prices and lowered waste ([#mkeyword]). Inevitably, the fostering of mass containers fosters a more efficient use of resources, adding to boosted functional efficiency and price financial savings in the supply chainLasting Product Packaging Solutions

A significant benefit of utilizing bulk containers hinges on their prospective to decrease waste in packaging procedures. These containers are made for reuse, considerably minimizing the requirement for single-use product packaging materials, which add to ecological deterioration. By consolidating item storage space and transportation, mass containers optimize room and reduce the overall quantity of materials required, thus lowering the carbon footprint connected with manufacturing and disposing of typical product packaging. In addition, their durability warranties that they can stand up to multiple journeys, promoting a circular economy. As businesses progressively adopt lasting methods, the integration of mass containers into supply chains stands for Plastic Bulk Containers a positive approach to minimizing waste and enhancing performance, eventually sustaining wider environmental objectives and corporate social duty initiatives.Enhancing Transport Efficiency

Enhancing transport efficiency is important for services utilizing bulk containers in item handling. Mass containers are made to maximize room usage throughout transport, permitting for bigger quantities of items to be shipped at the same time. This reduction in trips equates to reduce transportation costs and lowered carbon discharges, adding to even more lasting logistics techniques. Furthermore, the uniformity of bulk containers improves loading and unloading procedures, minimizing dealing with time and labor prices. Their strong building also offers protection against damages, decreasing losses throughout transportation. Therefore, business can accomplish quicker turnaround times, enhancing general supply chain efficiency. By carrying out bulk containers, services can greatly boost their transportation logistics, eventually leading to boosted productivity and an one-upmanship in the industry.Improving Product Safety and Top Quality

Ensuring product security and high quality is vital for services that utilize bulk containers in item handling, as these containers are particularly created to protect contents throughout storage space and transport. The durable construction of bulk containers protects products from ecological elements such as dust, dampness, and contamination, which can endanger stability. Furthermore, their airtight seals minimize exposure to air, therefore maintaining freshness and avoiding spoilage. Moreover, mass containers assist in compliance with safety laws by providing clear labeling and traceability, which are vital in various sectors, consisting of food and pharmaceuticals. By utilizing mass containers, companies can efficiently lower the threat of damages during transportation and handling, making sure that products reach their location in prime condition, therefore enhancing client fulfillment and trust.Adaptability and Flexibility of Mass Containers

Bulk containers use remarkable adaptability and flexibility, making them suitable for a vast array of applications and industries. Their design permits the reliable handling of numerous materials, consisting of granules, liquids, and powders, satisfying fields such as food, pharmaceuticals, and chemicals. These containers can be quickly changed or tailored to satisfy certain functional requirements, helping with smooth assimilation right into existing supply chains. Additionally, their stackable nature optimizes storage area, improving storehouse efficiency. The ability to stand up to different ecological problems better prolongs their usability across diverse setups, from producing to transportation. This versatility not just streamlines logistics yet additionally sustains services in conference changing needs, emphasizing the importance of bulk containers in modern item handling systems.

Sustainability Advantages of Making Use Of Mass Containers

The flexibility of bulk containers not just improves operational efficiency yet additionally contributes significantly to sustainability initiatives throughout different industries. By lowering the need for single-use product packaging, bulk containers minimize waste generation, causing a lower environmental impact. Their multiple-use nature enables companies to considerably decrease product consumption, while their layout promotes reliable transport, decreasing fuel intake and greenhouse gas discharges. Additionally, mass containers can be conveniently cleaned up and repurposed, even more extending their lifecycle and lessening the requirement for new manufacturing sources. This sustainable strategy lines up with growing customer choices for green methods, enabling organizations to enhance their brand name picture while supporting ecological stewardship. In general, the execution of bulk containers fosters a much more sustainable version for product handling and circulation.[#image]

Regularly Asked Questions

What Products Are Mass Containers Usually Made From?

Mass containers are generally made from products such as plastic, metal, wood, or composite materials. These options depend upon the container's intended use, resilience needs, and the kinds of products being saved or delivered.How Do Mass Containers Comply With Market Rules?

Bulk containers abide by sector regulations by sticking to safety and security requirements, making use of accepted materials, and assuring correct labeling. Regular evaluations and accreditations better assure they meet health, environmental, and transportation guidelines, safeguarding product honesty throughout the supply chain.[#image]

Can Mass Containers Be Customized for Particular Products?

Yes, bulk containers can be tailored for details items. Suppliers frequently develop them to meet distinct specs, making certain compatibility with numerous materials, improving protection, and maximizing effectiveness during handling and circulation customized to particular sector needs.What Is the Typical Life-span of a Bulk Container?

The typical life expectancy of a bulk container commonly varies from 5 to two decades, relying on the products made use of, regularity of usage, and upkeep techniques. Correct treatment can substantially expand its use and performance.[#video]

Just how Do I Tidy and Maintain Bulk Containers Efficiently?

To cleanse and keep bulk containers properly, one must frequently examine for damages, laundry with appropriate cleaning agents, rinse extensively, dry entirely, and store in a tidy, dry atmosphere to stop contamination and lengthen life expectancy. ([#mkeyword])The durability of mass containers frequently leads to less item damages throughout transportation, consequently lowering the demand for replacement product packaging. Reliable administration of product waste is an essential issue in item handling, and utilizing bulk containers can play a crucial role in resolving this issue. By combining item storage space and transportation, bulk containers maximize area and decrease the total volume of products needed, therefore reducing the carbon footprint connected with production and disposing of conventional product packaging. Enhancing transportation effectiveness is important for organizations using mass containers in product handling. Ensuring product safety and security and top quality is vital for businesses that use mass containers in product handling, as these containers are especially made to safeguard contents during storage and transportation.

Report this wiki page